In the world of healthcare and medical technology, ensuring the safety and effectiveness of medical devices is paramount. This is where ISO 14971, the international standard for risk management of medical devices, steps in as a guiding light. From pacemakers to diagnostic equipment, ISO 14971 provides a systematic framework for identifying, assessing, and mitigating risks associated with medical devices throughout their entire lifecycle. In this article, we delve into the intricacies of ISO 14971, exploring how it plays a pivotal role in safeguarding patients, enhancing product quality, and ensuring compliance with stringent regulatory requirements. Join us on a journey into the world of ISO 14971 risk management for medical devices, where safety meets innovation.

What is Risk Management?

Risk management is a systematic process of identifying, assessing, prioritizing, and mitigating risks or uncertainties that could affect the achievement of objectives, the success of a project, or the overall well-being of an organization. It is a fundamental business practice used in various fields, including finance, healthcare, project management, and information technology, to name a few.

Risk management is not just about avoiding or minimizing negative outcomes; it also encompasses the identification and pursuit of opportunities. In some contexts, this is referred to as “opportunity management” or “positive risk management,” where organizations seek to maximize the potential benefits of certain risks.

Effective risk management enables organizations to make informed decisions, allocate resources wisely, protect their assets, and enhance their ability to achieve their objectives while minimizing the adverse effects of unexpected events or uncertainties. It is a critical practice for maintaining resilience and adaptability in an ever-changing business and regulatory landscape.

What is ISO 14971?

ISO 14971 is an international standard that provides a framework for the risk management of medical devices. The standard defines the requirements for risk management and provides a framework for assessing and controlling safety risks associated with medical devices. ISO 14971 is widely adopted, and compliance is mandatory in many regions.

Today, there are three versions of ISO 14971: ISO 14971:2007, EN ISO 14971:2012, and ISO 14971:2019. The European market is covered by the EN standard. Outside of Europe, the most recent standard is ISO 14971:2019. The EN version of the standard adds three new appendices that have their own numbering system, which is not included in the ISO standard.

- Appendix A (Informative) – Overview of risk management

- Appendix B (Informative) – Illustrative examples

- Appendix C (Normative) – Guidance on the application of ISO 14971:2007 to software aspects of medical devices

Everywhere else across the globe, the ISO 14971:2019 version remains the current standard.

What Are The Key Terms In ISO 14971?

ISO 14971, the international standard for risk management of medical devices, contains several key terms and definitions that are fundamental to understanding and implementing the standard. Here are some of the key terms in ISO 14971:

- Benefit: The positive outcome of the use of a medical device when used under specified conditions.

- Hazard: A potential source of harm.

- Hazardous Situation: A circumstance in which people, property, or the environment are exposed to one or more hazards.

- Harm: Physical injury or damage to the health of people, or damage to property or the environment.

- Risk: The combination of the probability of occurrence of harm and the severity of that harm.

- Residual Risk: The risk remaining after risk control measures have been applied.

- Risk Acceptability: The level of risk that is tolerable in the context of the benefits provided by a medical device.

- Risk Analysis: The systematic use of available information to identify hazards and to estimate the risk.

- Risk Assessment: The overall process of risk analysis and risk evaluation.

- Risk Control: The process of implementing measures to reduce the risk to an acceptable level.

- Risk Evaluation: The process of comparing the estimated risk against given risk criteria to determine whether the risk is acceptable.

- Risk Management: The systematic application of management policies, procedures, and practices to the tasks of analyzing, evaluating, controlling, and monitoring risk.

- Risk Management Plan: A plan that specifies the objectives, methods, responsibilities, and criteria for risk analysis, evaluation, and control.

- Risk Reduction: Actions taken to reduce the probability of occurrence of harm or the severity of harm.

- Risk Residue: The remaining risk after risk control measures have been applied.

- Safety: Freedom from unacceptable risk.

- Usability: The extent to which a product can be used by specified users to achieve specified goals with effectiveness, efficiency, and satisfaction in a specified context of use.

- Use Error: An error made in the execution of a task in the use of a medical device, which can lead to harm.

- User: A person or organization that uses a medical device.

- User Error: An error made by the user that can lead to harm.

How Is ISO 14971 Compliance Important?

ISO 14971 compliance is critically important for various stakeholders in the medical device industry, as it plays a central role in ensuring the safety and effectiveness of medical devices. Here are some key reasons why ISO 14971 compliance is crucial:

- Patient Safety: The primary goal of ISO 14971 is to manage and mitigate risks associated with medical devices. Compliance with this standard helps ensure that medical devices are designed, manufactured, and used in a way that minimizes harm to patients, reducing the potential for adverse events, injuries, or even fatalities.

- Regulatory Requirements: Many regulatory authorities around the world, including the FDA (U.S.), the European Union’s MDR (Medical Device Regulation), and other national health authorities, require medical device manufacturers to demonstrate compliance with ISO 14971 as part of the regulatory approval process. Non-compliance can lead to delays in market access or even product recalls.

- Legal Liability: Failure to adhere to ISO 14971 and adequately manage risks can expose medical device manufacturers to legal liability in the event of injuries or harm caused by their products. Compliance can serve as a legal defense by demonstrating that a manufacturer followed recognized best practices for risk management.

- Market Access: ISO 14971 compliance is often a prerequisite for entering global markets. Having ISO 14971 certification can facilitate market access by demonstrating a commitment to safety and quality. Conversely, non-compliance can limit a company’s ability to sell its products internationally.

- Reputation and Trust: ISO 14971 compliance helps build trust and confidence among healthcare professionals, patients, and consumers. It signals that a manufacturer is committed to delivering safe and effective medical devices, which can enhance the company’s reputation and brand value.

- Product Quality: Effective risk management, as outlined in ISO 14971, can lead to improved product quality. Identifying and addressing potential issues early in the design and manufacturing processes can result in fewer product defects, recalls, and warranty claims, saving both money and reputation.

- Efficiency and Cost Savings: By systematically identifying and addressing risks throughout the product lifecycle, ISO 14971 compliance can lead to more efficient processes, reduced rework, and cost savings. Preventing problems is often more cost-effective than dealing with them after they occur.

- Continuous Improvement: ISO 14971 promotes a culture of continuous improvement in risk management. It requires organizations to monitor and review risk management processes and adapt them as necessary. This ongoing improvement can lead to safer and more innovative products.

- Interoperability: ISO 14971 provides a standardized framework for risk management in the medical device industry. This standardization facilitates communication and collaboration among different stakeholders, including manufacturers, regulatory authorities, and healthcare providers.

What Are The Compliance Requirements For ISO 14971?

ISO 14971 is an international standard that outlines the requirements for the application of risk management to medical devices. Compliance with ISO 14971 is crucial for manufacturers of medical devices to ensure the safety and effectiveness of their products. Here are the key compliance requirements for ISO 14971:

- Risk Management Process: ISO 14971 requires manufacturers to establish a systematic process for managing risks associated with their medical devices throughout the entire product lifecycle. This process includes risk assessment, risk analysis, risk evaluation, risk control, and ongoing risk monitoring.

- Risk Management Plan: Manufacturers must create a risk management plan that outlines the approach, responsibilities, and activities related to risk management. This plan should be documented and maintained throughout the product lifecycle.

- Risk Analysis: Manufacturers are required to conduct a thorough risk analysis to identify potential hazards associated with the medical device. This analysis should consider the likelihood of harm, the severity of harm, and the overall risk associated with each hazard.

- Risk Evaluation: After identifying hazards, manufacturers must evaluate the risks to determine if they are acceptable or if further risk control measures are necessary. This evaluation takes into account the benefits of the device compared to the identified risks.

- Risk Control: ISO 14971 mandates that manufacturers implement risk control measures to reduce or eliminate identified risks. These measures should be proportional to the level of risk and may include design changes, protective measures, or labeling requirements.

- Residual Risk Assessment: Manufacturers must assess the residual risks remaining after implementing risk control measures. Residual risks should be documented, and any necessary actions to further mitigate these risks should be taken.

- Benefit-Risk Analysis: ISO 14971 requires a benefit-risk analysis to ensure that the overall benefits of the medical device outweigh its potential risks. This analysis is a key factor in determining the acceptability of residual risks.

- Risk Management File: Manufacturers are required to maintain a risk management file that documents all risk management activities, including risk assessments, evaluations, and control measures. This file serves as evidence of compliance with ISO 14971.

- Post-Market Surveillance: ISO 14971 emphasizes the importance of post-market surveillance to continuously monitor and manage risks associated with a medical device after it has been placed on the market. Manufacturers must establish processes for collecting and analyzing post-market data.

- End-To-End Traceability: The standard emphasizes traceability throughout the risk management process, ensuring that there is a clear link between identified hazards, risk assessments, risk control measures, and other relevant documents and activities.

- Compliance Documentation: Manufacturers must maintain comprehensive documentation to demonstrate compliance with ISO 14971. This includes records of risk management activities, risk assessments, risk control measures, and other relevant documents.

Compliance with ISO 14971 is essential not only for regulatory approval but also for ensuring the safety and effectiveness of medical devices. Manufacturers must adhere to these requirements to minimize risks to patients and users and to meet their ethical and legal obligations.

How Are ISO 14971 And ISO 13485 Related?

ISO 14971 is closely related to ISO 13485, the international quality management standard for medical devices. ISO 13485 provides requirements for a quality management system that can be used by organizations that design, develop, manufacture, and/or provide medical devices. The standard covers risk management activities such as hazard identification, risk analysis, and risk control.

ISO 14791 and ISO 13485:2016 are linked because they form a QMS that is operational and protects against risk. Medical devices must meet regulatory and customer standards set forth in ISO 13485. Because any risk necessitates a risk analysis and record-keeping as stipulated by ISO 13485, it looks to ISO 14971 for assistance. When it comes to risk analysis, ISO 14971 provides a process to identify hazards, assess risks, and control risks.

The new ISO 13485 version improves risk management by including procedures such as purchasing and training. “The organization shall apply a risk-based approach to the control of the required processes for the quality management system,” reads section 4.2.1 in part.” In other words, anything that has an impact on the quality system’s performance needs to be assessed in light of this risk. This is not anything new, but it serves as a reminder that risk is an essential component of your QMS and must be addressed in order to obtain ISO 13485:2016 certification.

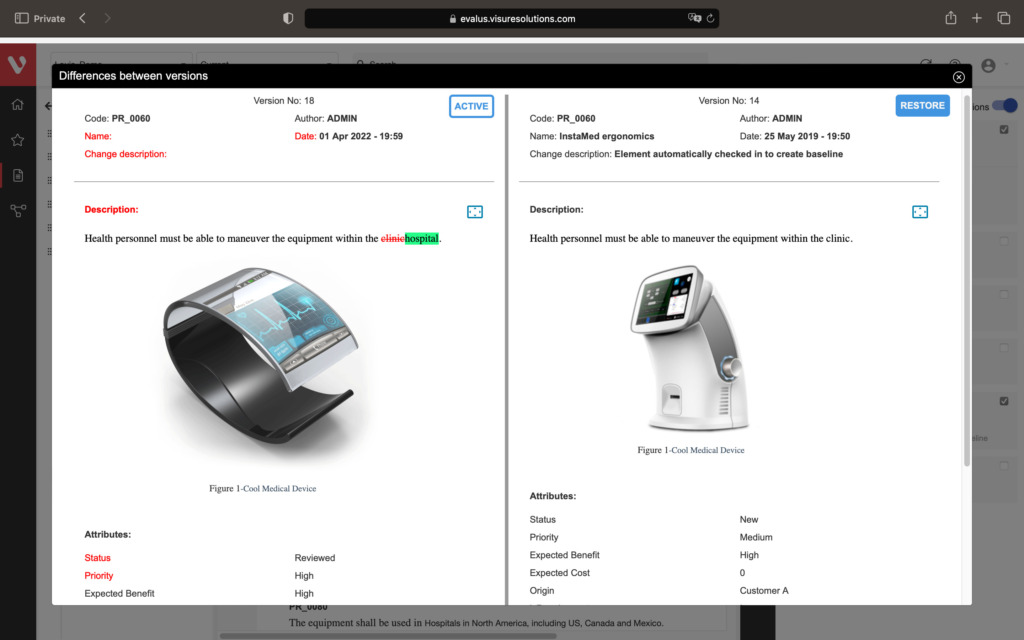

Visure Requirements ALM Platform:

The Visure Requirements ALM platform is a tool that helps organizations manage the requirements in accordance with ISO 14971. The platform includes risk analysis and management features that help organizations comply with ISO 14971.

Visure offers a seamless integration of risk management, testing, and requirements management within a unified platform, revolutionizing how you handle risks throughout your development process. With Visure, importing and cataloging risk factors is effortless, facilitating the swift implementation of the Failure Modes and Effects Analysis (FMEA) process and quantifying risks. Moreover, the identification of high-risk factors leads to the streamlined generation of corresponding Safety Requirements.

Visure empowers you to customize item types to align with your unique risk management approach, enabling proactive risk prevention and mitigation. Ultimately, Visure’s integrated software for risk, requirements, and testing management saves time and resources and ensures the delivery of a higher-quality product. It seamlessly aligns with ISO 14971 compliance requirements and best practices.

Visure Requirements ALM is a central hub that consolidates requirements, tests, defects, and risks within a unified platform, offering meticulous control and end-to-end traceability. This robust functionality empowers organizations to enforce their processes, ensuring compliance with ISO 14971, and facilitates the creation of essential deliverables that align with software safety classes.

Within Visure, teams effortlessly establish, enforce, and manage bidirectional traceability links across various levels of requirements decomposition, risk identification and mitigation, testing plans and results, problem reports and changes, software items, and more. This extends to intricate traceability connections between system requirements, software requirements, software system tests, risk control measures, hazards, and changes.

Visure automates the generation of traceability matrices and reports, while also providing comprehensive traceability views throughout the project, highlighting both upstream and downstream links. This comprehensive approach to traceability ensures that organizations can effectively navigate ISO 14971 compliance requirements while enhancing transparency and control across the entire development lifecycle.

Conclusion:

ISO 14971 is a regulatory standard for medical device manufacturers. The benefits of certification to this standard are many and include reducing the risk of product recalls, improving communication between departments within a company, and protecting patients from harm. Visure Requirements ALM Platform is a tool that can help companies achieve 14971 certification. Request a free 30-day trial at Visure Requirements ALM Platform today to see how our software can help your business meet the requirements of this important regulatory standard.