Introduction

In the aerospace industry, Aerospace Material Standards (AMS) play a crucial role in ensuring the safety, reliability, and performance of aircraft and spacecraft components. These standards define the material properties, manufacturing processes, and testing methods required for aerospace applications.

Developed and maintained by the Society of Automotive Engineers (SAE AMS), these standards set stringent guidelines for aerospace alloys, composites, coatings, and high-temperature materials. Compliance with AMS Standards in Aerospace Manufacturing is essential for meeting Aerospace Industry Regulations, ensuring durability, and maintaining operational efficiency.

This article provides a comprehensive breakdown of AMS Standards, explaining their purpose, key specifications, industry applications, and why achieving AMS Certification for Aerospace Materials is critical for manufacturers and suppliers.

What Are Aerospace Material Standards (AMS)?

Aerospace Material Standards (AMS) are globally recognized specifications that define the composition, properties, manufacturing processes, and quality requirements for materials used in aerospace applications. Developed by the Society of Automotive Engineers (SAE AMS), these standards ensure that materials used in aircraft, spacecraft, and defense systems meet stringent safety, performance, and durability requirements.

AMS standards cover a wide range of aerospace materials, including metals, composites, coatings, adhesives, and lubricants. By adhering to AMS specifications, manufacturers and engineers can ensure that materials meet Aerospace Engineering Standards for structural integrity, weight reduction, and resistance to extreme conditions.

How AMS Standards in Aerospace Manufacturing Define Material Properties, Performance, and Specifications

AMS standards provide detailed guidelines on:

- Material Composition – Ensuring aerospace alloys, composites, and coatings meet strict chemical and mechanical properties.

- Mechanical Performance – Defining tensile strength, fatigue resistance, and heat tolerance.

- Manufacturing Processes – Standardizing forging, machining, welding, and heat treatments for aerospace components.

- Testing and Certification – Establishing quality control protocols through Aerospace Material Testing to guarantee compliance with Aerospace Industry Regulations.

For instance, AMS for Aerospace Alloys and Composites ensures that materials used in aircraft structures can withstand high stress, thermal fluctuations, and corrosion, contributing to improved aircraft longevity and efficiency.

Importance of Standardization in Ensuring Aerospace Safety and Operational Efficiency

Standardization through AMS Standards in Aerospace Manufacturing is vital for:

- Aerospace Safety – Reducing the risk of material failure in flight-critical components.

- Regulatory Compliance – Meeting strict FAA, EASA, and NASA material approval requirements.

- Global Consistency – Enabling seamless material sourcing and compatibility across the aerospace supply chain.

- Cost Efficiency – Minimizing production errors and ensuring quality control through established Aerospace Quality Standards.

By implementing AMS Certification for Aerospace Materials, manufacturers can enhance their credibility, ensure compliance with Aerospace Material Compliance requirements, and maintain superior product performance in demanding aerospace environments.

Who Develops AMS Standards?

The Society of Automotive Engineers (SAE) is the primary organization responsible for developing and maintaining Aerospace Material Standards (AMS). Through its SAE AMS committee, the organization establishes stringent material specifications that define the composition, manufacturing processes, and performance requirements of materials used in aerospace manufacturing.

SAE AMS continuously updates these standards to keep pace with advancements in aerospace alloys, composites, and coatings, ensuring that aerospace materials meet evolving safety, durability, and performance demands.

Collaboration with Aerospace Manufacturers, Regulatory Agencies, and Suppliers

AMS standards are developed through a collaborative approach involving:

- Aerospace Manufacturers – Ensuring materials meet industry-specific design and performance needs.

- Regulatory Agencies – Aligning AMS with global Aerospace Industry Regulations, including FAA, EASA, and NASA requirements.

- Material Suppliers – Standardizing the production and quality of AMS-certified aerospace alloys and composites.

This collaboration helps maintain consistency in Aerospace Material Compliance, allowing engineers and manufacturers to source materials that meet industry-wide quality and safety benchmarks.

How AMS Certification Ensures Compliance with Aerospace Regulations

AMS Certification for Aerospace Materials verifies that materials conform to SAE AMS Standards and comply with stringent aerospace safety regulations. This certification process includes:

- Material Testing & Inspection – Ensuring compliance with AMS Standards in Aerospace Manufacturing through rigorous Aerospace Material Testing.

- Regulatory Approval – Meeting requirements set by agencies like the FAA and EASA to ensure airworthiness.

- Supply Chain Integrity – Guaranteeing that materials sourced from certified suppliers meet Aerospace Engineering Standards.

By adhering to AMS Standards, aerospace companies enhance operational efficiency, streamline production, and ensure their products meet the highest Aerospace Quality Standards for safety and reliability.

Key AMS Standards in Aerospace Manufacturing

Aerospace Material Standards (AMS) cover a broad range of materials essential for aerospace manufacturing, engineering, and compliance. These standards ensure that materials used in aircraft, spacecraft, and defense systems meet strict safety, durability, and performance criteria. Below are some of the most critical AMS standards in aerospace applications.

1. AMS for Aerospace Alloys and Composites

- AMS standards for aluminum, titanium, and nickel-based alloys define mechanical properties, corrosion resistance, and fatigue performance.

- Common AMS specifications:

- AMS 4911 – Titanium alloy for aerospace structures.

- AMS 4027 – Aluminum alloy for high-strength applications.

- AMS 5599 – Nickel-based superalloy for extreme environments.

- Role: Enhances aircraft durability, weight reduction, and fuel efficiency.

2. AMS for High-Temperature Materials

- Used in jet engines, exhaust systems, and heat shields, ensuring materials withstand extreme thermal and mechanical stress.

- Key AMS standards:

- AMS 5726 – Cobalt-based superalloy for turbine components.

- AMS 5679 – Heat-resistant stainless steel for engine applications.

- Role: Ensures thermal stability and resistance to oxidation and creep deformation.

3. AMS for Lightweight Structural Components

- Essential for reducing aircraft weight while maintaining structural integrity.

- Key AMS standards:

- AMS 4911 – Aerospace-grade titanium for lightweight, high-strength applications.

- AMS 4037 – Aluminum alloy for fuselage and wing structures.

- Role: Contributes to fuel efficiency, payload optimization, and enhanced maneuverability.

4. AMS for Aerospace Coatings and Treatments

- Critical for corrosion resistance, wear protection, and surface enhancement in aerospace materials.

- Key AMS standards:

- AMS 2460 – Hard anodizing for aluminum components.

- AMS 2404 – Electroless nickel coating for aerospace parts.

- AMS 2750 – Heat treatment process control for aerospace materials.

- Role: Enhances component longevity, reduces maintenance costs, and ensures compliance with aerospace regulations.

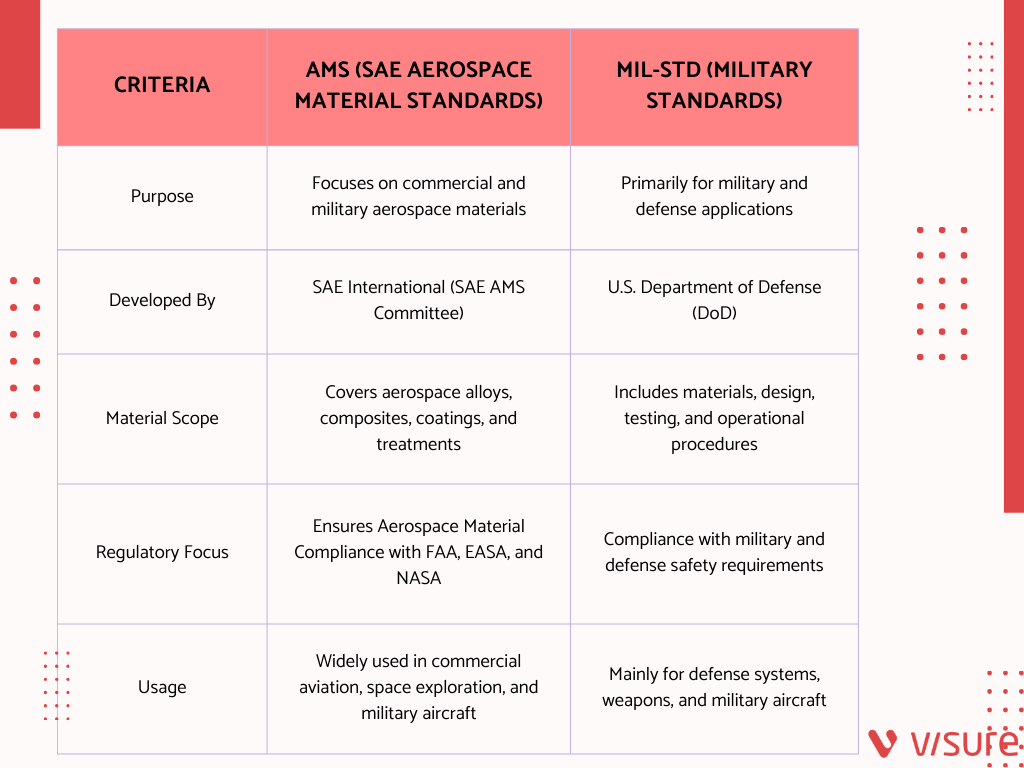

Comparison of AMS vs. MIL-STD: Key Differences in Aerospace Standards

Both AMS (Aerospace Material Standards) and MIL-STD (Military Standards) regulate aerospace materials, but they differ in scope and application:

While AMS Standards in Aerospace Manufacturing are widely adopted for commercial and defense applications, MIL-STD focuses on strict military compliance. Many aerospace components require dual compliance to meet both AMS and MIL-STD requirements for enhanced performance and Aerospace Safety Standards.

Why Are AMS Standards Critical in Aerospace Engineering?

Aerospace Material Standards (AMS) play a crucial role in ensuring Aerospace Material Compliance with stringent safety, regulatory, and performance requirements. Developed by the Society of Automotive Engineers (SAE AMS), these standards align with global aerospace regulations, including:

- FAA (Federal Aviation Administration) – Governs airworthiness and material safety.

- EASA (European Union Aviation Safety Agency) – Ensures compliance with European aerospace regulations.

- NASA & Military Standards (MIL-STD) – Oversee materials for space exploration and defense applications.

By adhering to AMS Certification for Aerospace Materials, manufacturers ensure that materials used in aircraft and spacecraft meet the highest Aerospace Engineering Standards for durability, corrosion resistance, and mechanical integrity.

How AMS Standards Ensure Aerospace Safety and Performance in Extreme Conditions

AMS standards define material properties and performance specifications for aerospace components that operate under high stress, temperature variations, and corrosive environments. Key aspects include:

- Heat Resistance – AMS for High-Temperature Materials ensures jet engines and exhaust systems can withstand extreme heat.

- Structural Integrity – AMS for Aerospace Alloys and Composites provides high-strength materials for aircraft fuselage and wings.

- Corrosion and Wear Protection – AMS for Aerospace Coatings and Treatments enhances longevity and maintenance efficiency.

By implementing AMS Standards in Aerospace Manufacturing, engineers can design aircraft that are lighter, stronger, and more fuel-efficient, ensuring optimal Aerospace Safety and Performance.

Aerospace Material Testing Methods for AMS-Compliant Materials

AMS-compliant materials undergo rigorous aerospace material testing to ensure quality and compliance. Common testing methods include:

- Mechanical Testing – Evaluates tensile strength, fatigue resistance, and impact durability.

- Thermal & Environmental Testing – Assesses material behavior under extreme temperatures, pressure, and humidity.

- Non-Destructive Testing (NDT) – Uses ultrasonic, radiographic, and magnetic particle inspection to detect internal defects.

- Chemical Analysis – Confirms material composition aligns with AMS specifications.

These testing methods guarantee that materials meet Aerospace Quality Standards, reducing the risk of failures in critical aerospace systems.

Benefits of Using AMS Standards in Aerospace Manufacturing

Implementing AMS Standards in Aerospace Engineering offers numerous advantages, including:

- Enhanced Safety & Compliance – Ensures all aerospace components meet FAA, EASA, and MIL-STD requirements.

- Improved Reliability & Performance – Reduces material failure risks in extreme aerospace environments.

- Cost Savings – Standardized materials minimize production errors, reducing rework and maintenance costs.

- Streamlined Supply Chain – Enables global material sourcing while maintaining consistent quality.

- Innovation & Sustainability – Supports the adoption of lightweight materials, advanced composites, and eco-friendly coatings.

By utilizing AMS-compliant Aerospace Materials, manufacturers enhance efficiency, maintain regulatory compliance, and improve the overall safety and longevity of aerospace systems.

Aerospace Industry Regulations and AMS Compliance

Aerospace Material Standards (AMS) are integral to meeting aerospace industry regulations, ensuring that materials used in aircraft, spacecraft, and defense systems comply with strict safety, performance, and durability requirements.

AMS certification verifies that aerospace materials conform to standardized specifications for strength, corrosion resistance, and thermal stability, reducing the risk of structural failures and ensuring airworthiness certification. Compliance with AMS standards is mandatory for:

- Aircraft manufacturers (Boeing, Airbus, Lockheed Martin).

- Aerospace suppliers producing alloys, composites, and coatings.

- Defense contractors working on military-grade components.

AMS certification ensures consistency, reliability, and global standardization in aerospace material sourcing and application, supporting full compliance with regulatory frameworks.

Role of Regulatory Bodies in Enforcing AMS Compliance

Several regulatory agencies mandate AMS compliance to uphold safety, quality, and performance in aerospace manufacturing:

FAA (Federal Aviation Administration)

- Enforces AMS standards for airworthiness certification and aircraft material approval.

- Regulates structural integrity, fatigue resistance, and corrosion protection in commercial and defense aircraft.

- Ensures compliance through material testing, inspection, and documentation.

EASA (European Union Aviation Safety Agency)

- Requires AMS-compliant materials in aircraft and aerospace component certification across Europe.

- Works alongside SAE AMS committees to align AMS standards with EU safety regulations.

- Mandates traceability and rigorous quality control for aerospace materials.

NASA (National Aeronautics and Space Administration)

- Uses AMS for Aerospace Alloys, Composites, and High-Temperature Materials in spacecraft and satellite design.

- Ensures thermal protection, radiation shielding, and mechanical reliability in extreme space environments.

- Collaborates with SAE International to establish AMS standards for next-generation aerospace materials.

By adhering to AMS Aerospace Standards, manufacturers can streamline regulatory approval, improve safety, and maintain compliance with global aerospace regulations.

Conclusion

Aerospace Material Standards (AMS) are essential for ensuring safety, reliability, and regulatory compliance in the aerospace industry. Developed by SAE International, AMS standards define the material properties, performance criteria, and testing methods required for aerospace applications, from high-temperature alloys to lightweight composites and protective coatings.

By adhering to AMS compliance, aerospace manufacturers can meet FAA, EASA, NASA, and military regulations, enhancing aircraft performance, reducing maintenance costs, and improving overall safety. Standardization through AMS also streamlines the supply chain, ensuring consistent material quality across global aerospace manufacturing.

Ensuring AMS compliance requires robust requirements management solutions to track, verify, and document materials used in aerospace engineering. Visure Solutions provides a powerful Requirements Management Platform designed to help aerospace organizations manage compliance, enhance traceability, and improve efficiency.

Start your 14-day free trial at Visure today and experience seamless Aerospace Standards Compliance!