DO-178C Guide: Introduction to RTCA DO-178 Certification

Table of Contents

3-Step Guide to Defining Requirements for Aerospace

Introduction

In the aerospace industry, requirements management is essential for ensuring the safety, reliability, and regulatory compliance of avionics systems. Poorly defined requirements can lead to costly redesigns, certification delays, and even mission failure. Given the complexity of airborne software and hardware development, a structured approach to requirements management in DO-178C and DO-254 is crucial for mitigating risks and ensuring project success.

The Importance of DO-178C and DO-254 Compliance

Compliance with DO-178C (Software Considerations in Airborne Systems and Equipment Certification) and DO-254 (Design Assurance Guidance for Airborne Electronic Hardware) is mandatory for avionics systems seeking FAA, EASA, and other regulatory approvals. These standards establish stringent guidelines for defining, managing, and verifying requirements to ensure system integrity and safety. Proper DO-178 requirements management and DO-254 requirements process implementation enable traceability, validation, and risk mitigation across the development lifecycle.

Challenges in Defining Requirements for DO-178C and DO-254

- Ensuring clarity and completeness: Requirements must be well-defined, unambiguous, and testable to comply with DO-178C and DO-254.

- Achieving full traceability: Every requirement must be linked to its corresponding design, implementation, and verification artifacts.

- Managing changes efficiently: Aerospace projects undergo frequent updates, making requirements version control and traceability critical.

- Meeting compliance verification demands: Auditors require evidence that DO-178 requirements software and DO-178 requirements tools have been used effectively to manage development and certification activities.

The 3-Step Guide to Effective DO-178 and DO-254 Requirements Management

To navigate these challenges, a structured, three-step approach ensures full compliance and efficiency in defining requirements for DO-178C and DO-254:

- Capture and Define Clear Requirements – Establishing precise, well-structured requirements to meet DO-178 and DO-254 standards.

- Ensure Compliance with DO-178C and DO-254 Standards – Implementing verification, validation, and traceability practices.

- Maintain Requirements Traceability and Change Management – Leveraging DO-178 requirements solutions for seamless requirement tracking and impact analysis.

By following this proven methodology, aerospace teams can streamline DO-178 and DO-254 requirements management, ensuring compliance, traceability, and efficiency in avionics development.

Step 1: Capture and Define Clear Aerospace Requirements

Defining requirements at the earliest stages of development is critical for ensuring compliance with DO-178C and DO-254. Poorly defined or ambiguous requirements can lead to costly rework, certification delays, and increased safety risks. DO-178 requirements management and DO-254 requirements process implementation must follow a structured approach to ensure consistency, traceability, and validation throughout the development lifecycle.

Best Practices for Writing Unambiguous, Testable, and Traceable Requirements

To ensure compliance with DO-178 and DO-254, aerospace requirements should be:

- Clear and unambiguous – Avoid vague or subjective terms. Each requirement must be precise and measurable.

- Testable and verifiable – Requirements must be written in a way that allows for objective validation and verification using DO-178 requirements solutions.

- Traceable – Every requirement should be linked to design, implementation, and testing artifacts, ensuring full requirements traceability.

- Prioritized and categorized – Classified requirements based on criticality, performance, and safety impact to streamline compliance efforts.

Key Elements of High-Quality Aerospace Requirements

Aerospace requirements should comprehensively address:

- Functional Requirements – Define how the system should operate under normal and failure conditions.

- Performance Requirements – Specify constraints like speed, power consumption, and response times.

- Safety Requirements – Ensure compliance with DO-178C and DO-254 safety objectives for airborne systems.

- Environmental Constraints – Address conditions such as temperature, pressure, and electromagnetic interference.

Tools and Methodologies for Capturing Aerospace Requirements Efficiently

Structured requirements capture methodologies, such as model-based systems engineering (MBSE) and structured textual analysis, improve requirements management in DO-178 and DO-254. Using DO-178 requirements tools and DO-254 requirements solutions, teams can:

- Standardize requirement templates and automate validation checks.

- Implement real-time collaboration for distributed teams.

- Integrate traceability matrices to ensure end-to-end coverage.

How DO-178 Requirements Tools Assist in Structured Requirement Gathering?

Modern DO-178 requirements software plays a pivotal role in defining and managing aerospace requirements, enabling:

- Automated requirement validation to detect inconsistencies early.

- Real-time traceability for tracking changes across the development lifecycle.

- Seamless integration with verification and validation processes to maintain DO-178C and DO-254 compliance.

By leveraging DO-178 requirements management tools, aerospace organizations can enhance requirements definition accuracy, minimize risks, and ensure regulatory compliance from project inception.

Step 2: Ensure Compliance with DO-178C and DO-254 Standards

DO-178C (Software Considerations in Airborne Systems and Equipment Certification) is the industry standard for developing airborne software in compliance with FAA, EASA, and other regulatory bodies. It mandates a structured requirements management process to ensure:

- Clear and testable software requirements linked to system-level needs.

- Traceability from requirements to code and test cases for verification.

- Rigorous validation and verification (V&V) to detect defects early.

- Configuration management to control requirement changes and maintain compliance.

Using DO-178 requirements tools, development teams can efficiently manage software requirements, maintain traceability, and automate compliance processes.

Key Principles of DO-254 Requirements Process for Airborne Hardware Development

Similar to DO-178C for software, DO-254 (Design Assurance Guidance for Airborne Electronic Hardware) applies to avionics hardware, requiring:

- Structured requirements definition for hardware components.

- Validation and verification at each development stage to mitigate risks.

- Full traceability of hardware requirements to ensure design integrity.

- Rigorous review processes for regulatory approval.

Implementing DO-254 requirements solutions helps ensure compliance by automating requirement tracking, validation, and documentation.

Role of Traceability in DO-178C and DO-254 Compliance

Requirements traceability is fundamental to proving compliance with DO-178C and DO-254. It ensures:

- Every requirement is linked to design, implementation, and testing artifacts.

- Impact analysis is streamlined when requirements change.

- Certification audits can verify that all requirements are properly validated and verified.

- Defects and inconsistencies are detected early, reducing certification risks.

Modern DO-178 requirements management solutions provide real-time traceability matrices to enhance compliance tracking.

Importance of Requirements Validation and Verification Throughout the Development Cycle

To meet DO-178C and DO-254 compliance requirements, organizations must implement a rigorous validation and verification (V&V) process, including:

- Requirement reviews to eliminate ambiguities.

- Test case generation to validate each software and hardware requirement.

- Regression testing to ensure changes do not impact compliance.

- Automated verification using DO-178 requirements software to streamline validation efforts.

How DO-178 Requirements Software Ensure Compliance?

Modern DO-178 requirements management tools enforce structured workflows, automating:

✅ Requirement capture and structuring for clarity and consistency.

✅ Traceability matrix generation to track changes and ensure compliance.

✅ Automated validation and verification to identify gaps early.

✅ Audit and certification reporting to facilitate regulatory approval.

By leveraging DO-178 requirements solutions and DO-254 requirements tools, aerospace organizations can enhance compliance, reduce manual effort, and accelerate certification timelines.

Step 3: Maintain Aerospace Requirements Traceability and Change Management

Traceability is a critical requirement in DO-178C and DO-254 compliance to ensure that every software and hardware requirement is linked to corresponding design, implementation, verification, and validation artifacts. Effective DO-178 requirements management enables:

- End-to-end visibility across the development lifecycle.

- Regulatory compliance verification for certification audits.

- Efficient defect tracking and impact assessment when requirements change.

- Minimized risks of inconsistencies between design, code, and test cases.

Without robust DO-178 requirements tools, manual tracking becomes time-consuming, error-prone, and non-compliant with certification standards.

How DO-178 Requirements Solutions Streamline Traceability, Impact Analysis, and Change Management?

Modern DO-178 requirements solutions provide:

✅ Automated bidirectional traceability – Ensuring all requirements are linked to relevant design, implementation, and test artifacts.

✅ Impact analysis tools – Evaluating the effects of changes before they are implemented.

✅ Version control and change tracking – Maintaining a history of requirement modifications to ensure consistency.

✅ Audit-ready documentation – Generating compliance reports for regulatory approval.

By using DO-178 requirements management software, teams can quickly assess and manage requirement changes while maintaining full traceability.

Best Practices for Managing Requirement Changes While Ensuring Compliance and Consistency

To maintain DO-178C and DO-254 compliance, organizations must implement structured change management practices, including:

- Formal change control processes to document and approve modifications.

- Impact analysis before implementing changes to evaluate risks.

- Versioning and baselining to maintain historical records of requirements.

- Automated alerts and notifications to track updates in real-time.

- Continuous validation and verification to confirm compliance after changes.

Role of DO-178 Requirements Tools in Automating Impact Analysis and Change Tracking

DO-178 requirements software plays a crucial role in automating impact analysis, allowing teams to:

- Instantly identify affected system components when a requirement changes.

- Ensure that all linked test cases and verification artifacts are updated accordingly.

- Prevent compliance gaps by enforcing structured change management workflows.

Advanced DO-178 requirements solutions integrate AI-powered traceability, reducing manual effort and ensuring full regulatory compliance.

How to Implement Best-in-Class Requirements Management in DO-178 and DO-254

To achieve best-in-class requirements management for DO-178C and DO-254, aerospace organizations should adopt:

✅ AI-driven requirements engineering platforms to enhance traceability and compliance.

✅ DO-178 requirements tools with real-time collaboration features for global teams.

✅ Integrated traceability matrices to visualize requirement relationships across the lifecycle.

✅ Automated compliance reporting to simplify FAA, EASA, and other regulatory audits.

By leveraging DO-178 and DO-254 requirements management software, aerospace teams can enhance efficiency, reduce compliance risks, and accelerate certification timelines.

Leveraging AI with Visure Requirements ALM Platform to Streamline Aerospace Requirements Management

Aerospace development demands precision, compliance, and traceability to meet stringent industry standards like DO-178C and DO-254. Managing these requirements manually is time-consuming, error-prone, and inefficient. Organizations must ensure:

- End-to-end traceability between requirements, design, verification, and validation.

- Strict compliance with regulatory standards.

- Efficient change management to handle evolving requirements.

This is where the AI-powered Visure Requirements ALM Platform revolutionizes DO-178 and DO-254 requirements management by enhancing efficiency, automation, and compliance.

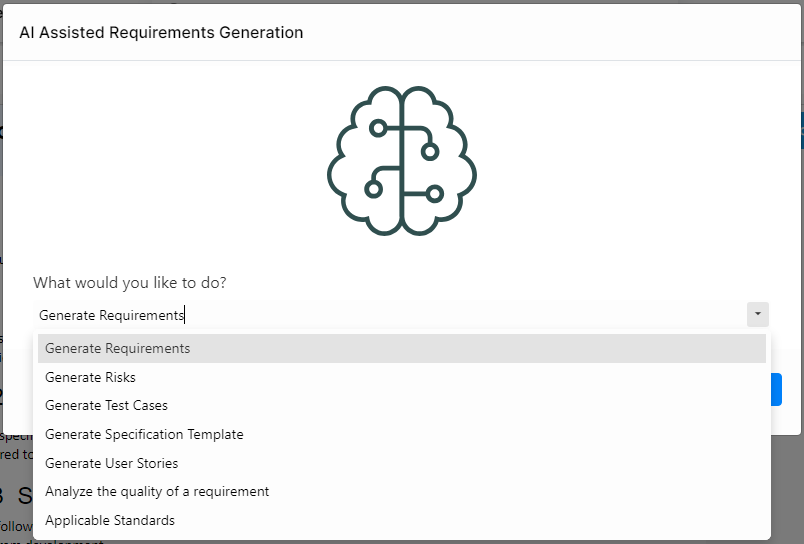

How AI Enhances DO-178 and DO-254 Requirements Management?

✅ Automated Requirement Generation & Validation

Visure AI assists in defining requirements for DO-178C and DO-254 by automatically:

- Generating consistent, testable, and high-quality requirements.

- Detecting ambiguities and inconsistencies early in the process.

- Suggesting corrections based on industry best practices.

✅ Traceability for Compliance

Enhanced traceability in DO-178 and DO-254 projects by:

- Automating bidirectional traceability between requirements, design, and test cases.

- Conducting real-time impact analysis when changes occur.

- Preventing compliance gaps by ensuring end-to-end requirement linking.

✅ Intelligent Change Management & Impact Analysis

With DO-178 requirements solutions integrated into Visure AI, organizations can:

- Predict the impact of requirement modifications across the entire lifecycle.

- Maintain automated version control to track historical changes.

- Reduce certification risks by ensuring full compliance documentation.

✅ Automated Verification & Compliance Audits

AI-driven DO-178 requirements tools in Visure help:

- Identify missing test cases and inconsistencies.

- Ensure every requirement is validated against compliance standards.

- Generate audit-ready reports for FAA, EASA, and regulatory approvals.

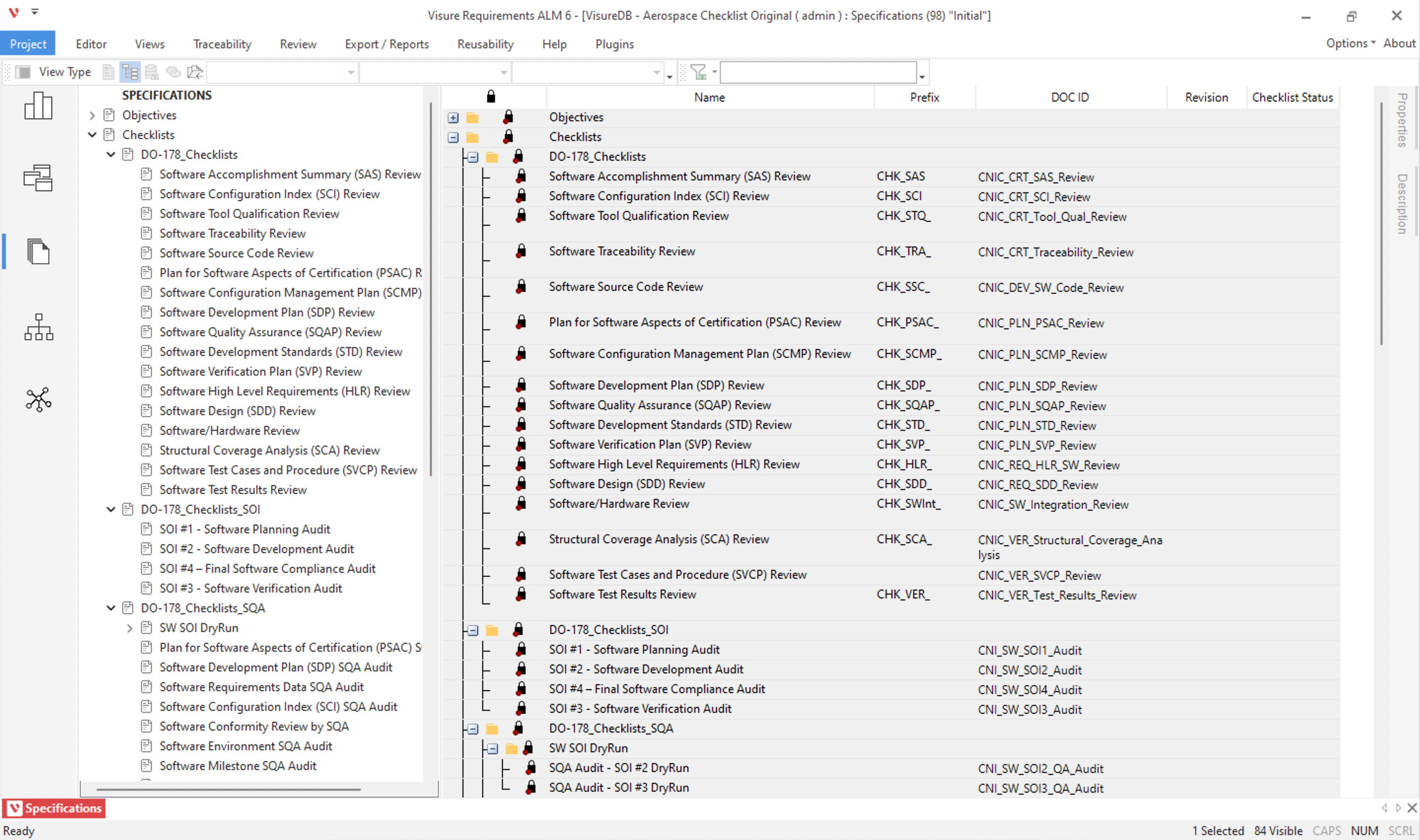

Why Choose Visure Requirements ALM for Aerospace Compliance?

- Complete DO-178 & DO-254 support – AI-driven requirements management tailored for aerospace.

- Seamless integration with lifecycle tools like IBM DOORS, JIRA, and MATLAB.

- Automation-first approach – Minimizing manual effort while maximizing compliance.

- Real-time collaboration – Enabling teams to work efficiently across global locations.

Conclusion

Effective DO-178 and DO-254 requirements management is essential for ensuring compliance, traceability, and efficiency in aerospace development. By leveraging AI-powered automation, teams can streamline requirements definition, validation, and traceability, significantly reducing certification risks and development time.

The Visure Requirements ALM Platform empowers aerospace organizations with AI-driven compliance, automated impact analysis, and seamless traceability, making it the ideal DO-178 and DO-254 requirements solution for modern development teams.

🚀 Take your aerospace requirements management to the next level with AI!

✅ Start your 30-day free trial of Visure today! Check it out here.

Don’t forget to share this post!

Chapters

1. Airborne Standard Introduction

2. DO-178 Certification Process

3. DO-178C Tools & Trainings

4. Advanced DO-178C Topics

5. DO-178C Resources

6. Glossary

Get to Market Faster with Visure

- Ensure Regulatory Compliance

- Enforce Full Traceability

- Streamline Development

Start Gaining End-to-End Traceability Across Your Projects with Visure Today

Start 30-day Free Trial Today!