Long gone are the days when safety practices in the automotive industry were a mere afterthought. Today, all major car manufacturers rely on a standardized set of practices that help them design safer cars more efficiently. One such set of practices was released in 2011 by the International Organization for Standardization (ISO) in collaboration with the International Electrotechnical Commission (IEC) to address the functional safety of electrical and/or electronic systems, and it’s called ISO 26262.

What Is ISO 26262?

Unlike other standards in the car industry, ISO 26262 focuses on functional safety, which means that it ensures that individual components do what they have been designed to do and when they are supposed to do it.

By complying with this standard, car manufacturers can avoid or at least minimize systemic failures, minimize the risk of harm to people, ensure compliance with relevant international regulations, avoid costly product recalls and reputational damage, and generally maintain their competitive advantage.

Other standards have a different focus. MISRA (Motor Industry Reliability Association) focuses on security and deals with software developed for electronic components used in the car industry. SAE J3061 from the Society of Automotive Engineers (SAE) provides an engineering process to design and build cybersecurity into vehicle systems in a comprehensive and systematic way. AEC-Q100 from the Automotive Electronics Council deals with stress testing for integrated circuits in automotive applications.

Overview of ISO 26262

ISO 26262 consists of 9 normative parts and a guideline, some of which are further divided into sub-chapters:

1. Vocabulary

This part specifies key terms like “fault” vs. “error” vs. “failure” and highlights the differences between them.

2. Management of functional safety

This part deals with overall safety management, project-dependent safety management, and safety management regarding production, operation, service, and decommissioning.

3. Concept phase

This part includes item definition, hazard analysis and risk assessment, and functional safety concept.

4. Product development at the system level

This part explains the general topics for the product development at the system level, along with technical safety concept, system and item integration, testing, and safety validation.

5. Product development at the hardware level

This part deals with general topics for the product development at the hardware level, specification of hardware safety requirements, evaluation of the hardware architectural metrics, evaluation of safety goal violations due to random hardware failures, and hardware integration and verification.

6. Product development at the software level

This part provides information about general topics for the product development at the software level, specification of software safety requirements, and software architectural design.

7. Production, operation, service, and decommissioning

This part describes planning for production, operation, service and decommissioning.

8. Supporting processes

This lengthy part includes interfaces within distributed developments, specification and management of safety requirements, configuration management, change management, verification, documentation management, confidence in the use of software tools, qualification in the use of software tools, qualification of software components, evaluation of hardware elements, proven in use argument, interfacing an application that is out of scope of ISO 26262, and integration of safety-related systems not developed according to ISO 26262.

9. Automotive Safety Integrity Level (ASIL)-oriented and safety-oriented analysis

This important part deals with requirements decomposition with respect to ASIL tailoring, criteria for the coexistence of elements, analysis of dependent failures, and safety analysis. ASIL is a key component of ISO 26262 compliance because it seeks to specify the consequences of a failure to the driver and associated road users based on a combination of the severity, exposure and controllability of the vehicle operating scenario. Depending on the severity of the consequences, safety requirements are assigned an ASIL of A, B, C, or D, with D being used for the most safety-critical requirements.

10. Guideline on ISO 26262

Finally, the last part serves as a concise guideline on ISO 26262, listing its scope, normative references, and key concepts.

Together, the different parts of ISO 26262 provide a system of steps with the purpose of helping car manufacturers regulate product development on a system, hardware, and software level and manage functional safety. The steps cover the entire development process, including requirements specification, design, implementation, integration, verification, validation, and configuration.

How to Support ISO 26262

There are many important benefits associated with adherence to ISO 26262. Those who comply with this standard can ensure that E/E safety hazards don’t suddenly emerge later in the production process when it costs significantly more to fix them.

However, adherence to ISO 26262 also requires extensive documentation and testing, both of which can be extremely time-consuming without the right tool to support them. To successfully overcome the numerous compliance challenges associated with ISO 26262, development teams should use a capable requirements management tool to make ISO 26262 compliance easier, less error-prone, and more cost-effective.

Visure Requirements and ISO 26262

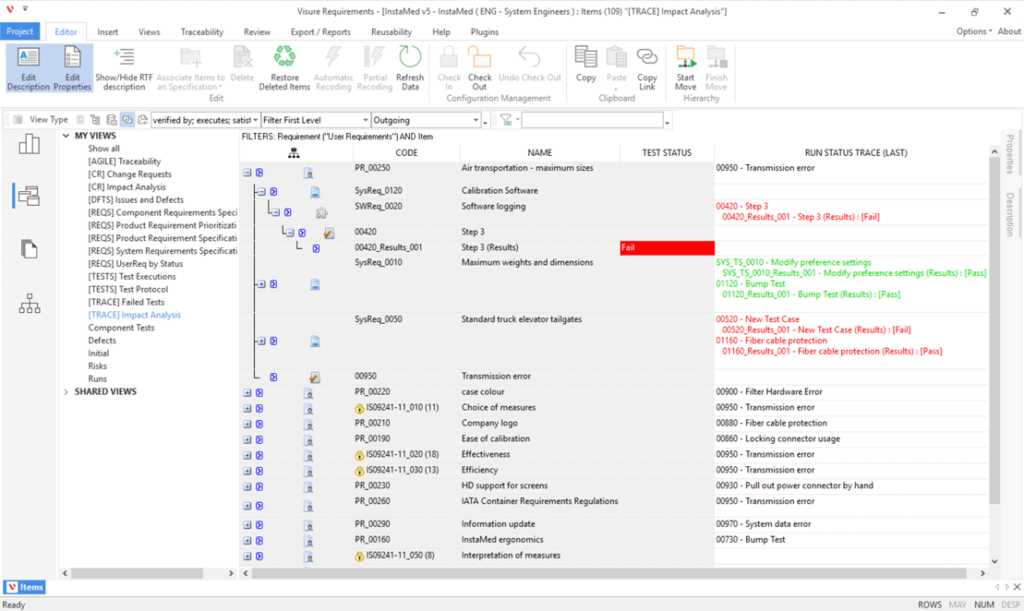

Visure Requirements can support ISO 26262 with its comprehensive and agile artifact management for the development and verification of electrical and/or electronic systems in production vehicles. In one cohesive environment, it provides end-to-end traceability between all the items, hazards, safety goals, risks, safety requirements, verification, changes, and project artifacts, helping users comply with ISO 26262 and create the necessary deliverables to meet the desired ASIL Levels.

By providing a centralized and open repository for all artifacts, Visure Requirements delivers end-to-end traceability between them for full impact analysis, hazard analysis, and risk management. It promotes collaboration by allowing several users to work with the very same set of requirements at the same time keeping traces and reports of every change with a complete versioning system. It also provides a versatile Integration Platform to integrate with third-party tools and extend the capabilities of Visure Requirements while keeping everything centralized.

Conclusion

The benefits of ISO 26262 are impossible to ignore but the same can be said about its requirements, which can be very time-consuming to fulfill without the right requirements management tool. Visure Requirements is designed to provide integral support to the complete requirement process, making it fully capable of supporting ISO 26262 for the production of electrical and/or electronic systems in production vehicles.