Introduction

In today’s fast-evolving mobility landscape, effective risk management in the automotive industry is not just a regulatory requirement—it’s a strategic imperative. With the growing complexity of modern vehicles, especially those involving connected, autonomous, and electric systems, the automotive sector faces increasing exposure to safety, cybersecurity, and compliance risks.

Implementing a robust automotive risk management strategy enables manufacturers, OEMs, and suppliers to proactively identify, assess, and mitigate potential hazards across the entire automotive product development lifecycle. From ensuring compliance with ISO 26262 for functional safety to addressing cybersecurity threats in connected vehicles, risk management is at the heart of delivering safe, reliable, and regulation-compliant products.

This guide explores the automotive industry risk assessment process, key challenges, risk mitigation strategies, industry standards, and the latest risk management tools and software solutions that help organizations stay compliant, agile, and competitive.

What is Automotive Risk Management?

Automotive Risk Management refers to the structured process of identifying, assessing, mitigating, and monitoring potential risks throughout the automotive development lifecycle. These risks can range from functional safety hazards and supply chain disruptions to cybersecurity threats and regulatory non-compliance. The goal is to ensure that vehicles and their components operate safely and reliably under all conditions while meeting global safety and automotive compliance standards.

Why Risk Management Is Critical in Automotive Development

As vehicles become more complex—with increased software integration, electronic control units (ECUs), and connectivity—so do the potential failure points. A single risk left unaddressed can lead to system failures, product recalls, or even life-threatening accidents. That’s why risk management in the automotive industry is vital for ensuring product safety, protecting brand reputation, and achieving compliance with industry standards like ISO 26262 and ASPICE.

Overview of Industry Challenges and Safety Concerns

The automotive sector faces unique challenges, including:

- Tight development timelines with growing technical complexity

- Risks from third-party suppliers in the automotive supply chain

- Increasing threats to automotive cybersecurity from connected and autonomous systems

- Rising pressure to comply with evolving regulatory requirements

These challenges highlight the need for a proactive and integrated automotive industry risk assessment strategy across every stage of development.

Role of Functional Safety and Compliance in Reducing Risks

Functional safety—as defined by ISO 26262—plays a foundational role in reducing risks in safety-critical automotive systems. Compliance with functional safety standards ensures that potential hazards are identified early, systematically analyzed, and appropriately mitigated through the vehicle’s design and software architecture.

Furthermore, alignment with automotive regulatory requirements and international frameworks not only ensures legal compliance but also builds consumer trust and enhances overall system resilience.

Key Risks in Automotive Development and Production

The rise of intelligent, software-driven, and connected vehicles has significantly amplified the risk landscape in the automotive sector. Identifying and mitigating these risks early in the automotive development lifecycle is essential for ensuring safety, compliance, and performance. Below are the most critical categories of risk affecting the industry today.

Safety Risks in Vehicle Systems and Electronics

Modern vehicles rely heavily on advanced electronic control systems, sensors, and embedded software. A single malfunction in these systems can compromise functional safety, leading to system failures or endangering passengers. This makes automotive risk management essential for preventing hardware and software defects that could result in safety incidents, recalls, or violations of automotive industry safety standards.

Automotive Supply Chain Risk and Logistics Disruptions

The global automotive supply chain is vast, complex, and often fragile. Disruptions caused by geopolitical issues, material shortages, or supplier non-compliance can severely delay production and increase costs. Managing automotive supply chain risk through strategic sourcing, redundancy planning, and supplier risk assessment is critical to ensuring continuity and meeting market demands.

Cybersecurity Risks in Connected and Autonomous Vehicles

As vehicles become increasingly connected through over-the-air updates, IoT, and V2X (vehicle-to-everything) communication, they become more vulnerable to cyberattacks. Cybersecurity risks in connected and autonomous vehicles can lead to data breaches, operational disruptions, or even life-threatening control compromises. Effective cyber risk management and compliance with standards like ISO/SAE 21434 are essential for safeguarding both vehicle performance and user privacy.

Software and Hardware Integration Risks

Seamless integration of automotive software and hardware is crucial—but highly complex. Incompatible components, version mismatches, and interface failures can result in system breakdowns. Addressing these integration challenges early through risk analysis in automotive development and robust testing protocols helps avoid downstream failures and ensures reliability across the vehicle safety lifecycle.

Regulatory Requirements and Industry Standards

To ensure automotive functional safety and mitigate potential hazards, the industry must comply with a range of international standards and regulations. These standards form the backbone of effective risk management in the automotive industry, guiding OEMs and suppliers in building safe, secure, and regulation-compliant vehicles.

ISO 26262 for Functional Safety

ISO 26262 is the cornerstone of automotive functional safety. It provides a structured framework for identifying, assessing, and mitigating safety risks in electrical and electronic systems throughout the automotive product development lifecycle. Covering everything from hazard analysis and risk assessment to safety validation, ISO 26262 ensures that risks are addressed systematically and early in the development process.

For both OEMs and Tier-1 suppliers, ISO 26262 risk management is essential to avoid system failures, meet legal requirements, and maintain consumer trust in today’s safety-critical automotive systems.

Role of ASPICE and ISO/PAS 21448 (SOTIF)

In addition to ISO 26262, two other key standards shape the automotive safety engineering landscape:

- ASPICE (Automotive SPICE) focuses on evaluating and improving software and systems development processes. It ensures that safety-critical software is developed in a controlled, quality-assured manner.

- ISO/PAS 21448 (SOTIF) addresses the Safety Of The Intended Functionality, particularly for advanced driver-assistance systems (ADAS) and autonomous vehicles. It covers scenarios where systems behave as intended but may still cause harm due to external or unforeseen conditions.

Together, these standards help organizations reduce vehicle safety risks, improve traceability, and implement best practices for automotive functional safety and risk control.

Automotive Regulatory Requirements for OEMs and Suppliers

Global OEMs and suppliers must comply with stringent automotive regulatory requirements across regions such as the EU, US, and Asia. These regulations govern everything from cybersecurity risk management and emissions to safety recalls and software updates.

To meet these demands, manufacturers must adopt an integrated risk management framework for automotive OEMs and suppliers—one that aligns with evolving industry standards and regulatory expectations. Failure to do so can result in legal penalties, production delays, and reputational damage.

Best Practices for Effective Automotive Risk Management

To successfully implement automotive risk management, organizations must adopt structured, proactive, and standards-aligned processes. These best practices ensure that risks are identified early, thoroughly analyzed, and continuously monitored throughout the automotive development lifecycle.

Risk Identification and Early Assessment Strategies

Effective risk management in automotive development begins with early and continuous risk identification. During the concept and system design phases, teams should conduct detailed hazard analyses, review historical failure data, and evaluate functional architectures for potential vulnerabilities. The earlier the risks are detected, the lower the cost and effort required to mitigate them.

Establishing a cross-functional approach that includes systems engineers, software developers, and quality teams ensures full visibility across the automotive safety lifecycle.

Quantitative and Qualitative Risk Analysis Techniques

A combination of quantitative and qualitative risk analysis is essential to evaluate the severity, occurrence, and detectability of risks. Techniques include:

- Risk scoring models that assign numerical values based on impact and probability

- Risk heat maps for visualizing high-priority issues

- Root cause analysis and fault tree analysis (FTA) for deep investigations into system-level failures

These techniques support data-driven automotive industry risk assessment and enable informed decisions on where to focus mitigation efforts.

Integrating Risk Management into the Automotive Software Safety Lifecycle

Risk should not be treated as a standalone function—it must be embedded into every phase of the automotive software safety lifecycle. This includes requirements definition, software architecture design, implementation, verification, and validation.

Tools that support traceability, change impact analysis, and automated risk updates help ensure continuous alignment with automotive functional safety standards like ISO 26262, ASPICE, and SOTIF.

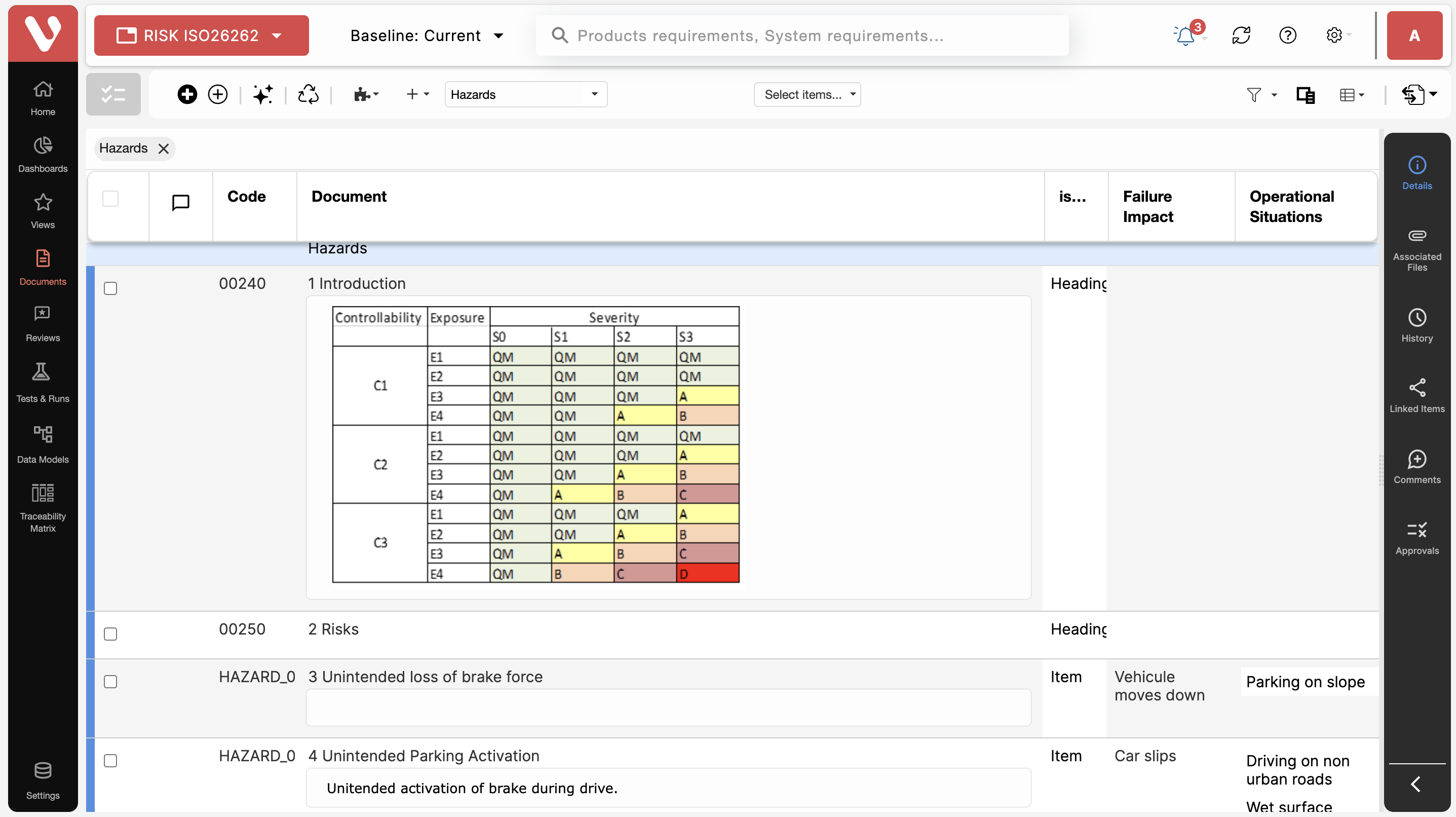

Using Risk Matrices and FMEA in Automotive Projects

Tools like risk matrices and Failure Mode and Effects Analysis (FMEA) are fundamental in evaluating and prioritizing risks in automotive projects.

- Risk matrices visualize severity vs. likelihood, helping teams focus on critical areas.

- FMEA identifies potential failure modes, their effects, and controls to mitigate them—making it an essential part of automotive supply chain risk management and system design.

Applying these tools throughout development helps ensure a comprehensive and traceable approach to risk mitigation in automotive systems.

Automotive Risk Management Tools and Software Solutions

Managing complex risks across the automotive development lifecycle requires robust, integrated software tools that ensure traceability, compliance, and collaboration. Leading automotive risk management tools and software solutions help organizations streamline risk identification, perform detailed analyses, and maintain alignment with industry standards like ISO 26262, ASPICE, and SOTIF.

Visure Requirements ALM Platform

The Visure Requirements ALM Platform stands out as a leading automotive risk management solution purpose-built for safety-critical industries. It offers end-to-end support for the requirements engineering lifecycle, including:

- AI-powered Risk identification, analysis, and prioritization using customizable risk matrices and FMEA templates

- Full traceability across requirements, risks, test cases, and design artifacts

- Seamless alignment with ISO 26262, ASPICE, ISO/PAS 21448 (SOTIF), and other automotive regulatory requirements

- Built-in templates and workflows for functional safety compliance and audit readiness

- Integration with modeling, testing, and ALM tools for complete lifecycle coverage

By integrating risk management into the software and hardware development process, Visure enables organizations to mitigate safety and compliance risks early, reducing rework, improving product quality, and accelerating certification processes.

Whether you’re an OEM, Tier-1 supplier, or systems integrator, the Visure ALM Platform delivers the agility and reliability needed to manage risks in complex automotive engineering environments.

Future Trends in Automotive Risk Management

As the automotive industry accelerates toward electrification, autonomy, and connectivity, risk management in automotive development must evolve to address new and more dynamic challenges. From AI-driven risk prediction to real-time monitoring, the future of automotive risk management will be shaped by advanced technologies and continuously evolving standards.

AI and Machine Learning for Predictive Risk Management

Artificial intelligence (AI) and machine learning (ML) are transforming traditional risk management processes. By analyzing historical project data, sensor logs, and failure reports, AI-powered risk management solutions can:

- Identify hidden patterns in automotive software and hardware integration risks

- Predict high-risk areas before issues arise

- Recommend risk mitigation strategies with higher accuracy

These capabilities enable predictive automotive risk management, allowing OEMs and suppliers to proactively address vulnerabilities during early development phases and throughout the automotive product lifecycle.

Real-Time Risk Monitoring in Connected Vehicles

The increasing connectivity of vehicles introduces a new dimension to automotive cybersecurity risk management. With real-time data from IoT sensors, V2X communications, and over-the-air updates, companies can now implement real-time risk monitoring systems that:

- Detect cyber threats and anomalies instantly

- Monitor system health and safety functions in live environments

- Trigger automatic mitigation protocols and alerts

This real-time visibility is essential for managing safety risks in connected and autonomous vehicles and enhancing post-deployment risk control in the automotive industry.

Evolving Standards and the Future of Functional Safety

The automotive standards landscape is evolving to keep pace with technology. In addition to ISO 26262 and ASPICE, new frameworks like ISO/SAE 21434 (automotive cybersecurity) and updates to ISO/PAS 21448 (SOTIF) are becoming essential for covering emerging risks in AI-driven and autonomous vehicle systems.

Future automotive functional safety standards will likely incorporate:

- Continuous safety validation for machine learning-based systems

- Lifecycle coverage of software-defined vehicles

- Integrated cybersecurity and functional safety requirements

To stay compliant and competitive, organizations must align their risk management frameworks with these evolving automotive industry safety and compliance requirements.

Conclusion

In today’s rapidly evolving automotive landscape, effective risk management is not just a best practice—it’s a strategic necessity. From addressing safety risks in vehicle electronics to managing cybersecurity threats in connected vehicles and ensuring compliance with evolving standards like ISO 26262, ASPICE, and SOTIF, manufacturers must adopt a structured, forward-thinking approach.

Implementing best practices such as early risk identification, quantitative and qualitative analysis, and seamless integration into the automotive software safety lifecycle is essential to reduce failures, meet regulatory requirements, and accelerate innovation.

With advanced tools like the Visure Requirements ALM Platform, organizations can gain full traceability, automate compliance, and drive smarter, safer automotive development.

Start your 14-day free trial with Visure Requirements ALM Platform today and experience end-to-end risk and requirements management built for the automotive industry.