In today’s fast-evolving industrial landscape, Product Lifecycle Management (PLM) plays a pivotal role in managing the end-to-end lifecycle of a product—from its initial concept to design, manufacturing, and eventual disposal. However, traditional PLM systems often struggle with inefficiencies, data silos, and limited predictive capabilities.

This is where Artificial Intelligence (AI) steps in as a game-changer. By integrating AI into PLM processes, businesses can harness the power of predictive analytics, real-time data insights, and automation, enabling smarter decision-making and enhanced product innovation. From optimizing product designs to streamlining manufacturing and maintenance, AI-driven PLM solutions are transforming how organizations approach the product lifecycle.

In this article, we explore how AI-enabled PLM software addresses the challenges of traditional systems, its applications across lifecycle stages, and the industries benefiting from these advancements. Discover how embracing AI in Product Lifecycle Management can revolutionize your processes and position your business for long-term success.

AI in Product Lifecycle Management

What is Product Lifecycle Management (PLM)?

Product Lifecycle Management (PLM) is a strategic process that manages a product’s entire lifecycle, from initial conception and design to production, deployment, maintenance, and disposal. It acts as a centralized framework for integrating people, processes, and technology across all stages of the product lifecycle.

PLM is essential in modern industries for:

- Streamlining operations by improving collaboration and decision-making.

- Enhancing product quality through better design and testing.

- Reducing time-to-market by optimizing workflows and communication.

- Cost control by identifying inefficiencies early in the process.

How Artificial Intelligence (AI) is Transforming PLM?

The integration of Artificial Intelligence (AI) into PLM systems is revolutionizing the way organizations manage product lifecycles. AI brings powerful capabilities, such as:

- Predictive Analytics: Forecasting demand, identifying potential issues, and enabling proactive decision-making.

- Automation: Streamlining repetitive tasks, like data entry, quality checks, and resource allocation.

- Real-Time Insights: Providing actionable data for faster and more accurate decision-making.

- Enhanced Design and Testing: Leveraging machine learning to optimize designs and detect defects early.

- Smart Maintenance: Using predictive algorithms to anticipate maintenance needs and reduce downtime.

By leveraging AI-driven PLM solutions, businesses can overcome the limitations of traditional PLM systems, unlock new levels of efficiency, and foster innovation. This transformation is particularly significant for industries like automotive, aerospace, consumer electronics, and manufacturing, where agility and precision are critical to success.

What are the Key Challenges in Traditional Product Lifecycle Management (PLM)?

While Product Lifecycle Management (PLM) systems are vital for managing products through their lifecycle, traditional approaches face several challenges that limit efficiency and effectiveness:

- Data Silos:

- Data is often scattered across multiple systems, departments, and locations, making it difficult to access and integrate information for informed decision-making.

- This lack of cohesion can lead to miscommunication, delays, and errors in the product lifecycle.

- Inefficiency in Processes:

- Manual processes and redundant workflows increase operational complexity, slowing down time-to-market.

- Collaboration across teams and supply chains becomes cumbersome without seamless data sharing and automation.

- Lack of Predictive Capabilities:

- Traditional PLM systems lack tools for forecasting trends, identifying potential risks, or optimizing resource allocation.

- Businesses miss opportunities to proactively address challenges, leading to reactive decision-making and higher costs.

- Limited Real-Time Insights:

- Static data models fail to provide real-time updates, making it harder to adapt to changing market demands or resolve issues promptly.

Why Businesses Need AI-Enabled PLM Solutions?

The limitations of traditional PLM underscore the need for AI-driven product lifecycle solutions that can deliver:

- Enhanced Decision-Making:

- AI-powered predictive analytics enable businesses to anticipate market demands, identify potential bottlenecks, and optimize workflows for better outcomes.

- Automation and Efficiency:

- AI in PLM software automates repetitive tasks, reduces errors, and ensures smoother processes, freeing teams to focus on innovation.

- Real-Time Data Integration:

- By breaking down data silos, AI provides real-time insights that allow teams to collaborate effectively and adapt quickly to changes.

- Improved Product Quality:

- Machine learning algorithms analyze historical and real-time data to identify defects, optimize designs, and ensure higher product reliability.

- Cost and Time Savings:

- With AI-powered PLM solutions, businesses can reduce time-to-market, minimize waste, and manage resources more efficiently.

Adopting AI-enabled product lifecycle management is no longer a luxury but a necessity for companies striving to stay competitive in today’s dynamic market environment. AI offers the tools to address traditional challenges and unlock new levels of productivity, innovation, and value creation.

Benefits of AI in Product Lifecycle Management (PLM)

Predictive Analytics

AI-driven predictive analytics transforms forecasting by leveraging vast amounts of historical and real-time data. This enables businesses to:

- Accurately predict product demand: Prevent overproduction or stock shortages by identifying trends and market behavior.

- Optimize resource allocation: Anticipate material and workforce needs, reducing waste and improving efficiency.

- Identify potential risks early: Predict bottlenecks, failures, or delays, enabling proactive problem-solving.

Real-Time Data Analytics

Traditional PLM systems struggle with static data, while AI-powered PLM solutions process real-time information to:

- Provide actionable insights across all stages of the product lifecycle.

- Enhance agility by allowing teams to adapt quickly to changes in design, production, or market demand.

- Enable data-driven decisions for improved outcomes and reduced time-to-market.

Automation of Repetitive Tasks

Repetitive tasks in PLM, such as data entry, quality checks, and document management, consume valuable time. AI addresses this by:

- Automating mundane processes, reducing human error and speeding up workflows.

- Allowing designers and engineers to focus on innovation and strategic tasks.

Enhanced Collaboration

AI-powered tools foster seamless communication and collaboration by:

- Integrating data across teams, suppliers, and stakeholders into a single platform.

- Natural language processing (NLP) is used to provide contextual insights and aid decision-making.

- Facilitating real-time updates to ensure everyone stays aligned throughout the product lifecycle.

By leveraging AI in Product Lifecycle Management, organizations can unlock unprecedented levels of efficiency, innovation, and competitiveness. These benefits make AI-powered PLM solutions indispensable for businesses aiming to thrive in today’s fast-paced markets.

AI Applications in Product Lifecycle Stages

Design and Development

AI revolutionizes the design and development phase by using machine learning algorithms to create smarter, optimized products:

- Optimizing Product Designs: Machine learning analyzes historical and real-time data to recommend design improvements, detect flaws, and simulate performance before production.

- Prototyping Efficiency: AI shortens the prototyping cycle by automating design iterations and enhancing accuracy with predictive modeling.

Manufacturing and Production

AI transforms manufacturing by enabling process automation and quality assurance, ensuring streamlined production cycles.

- Automation: AI-driven robotics and algorithms automate repetitive production tasks, improving consistency and reducing errors.

- Quality Assurance: Computer vision and AI-based inspection systems detect defects during production, ensuring high-quality outputs.

- Reducing Production Delays: AI-powered PLM software predicts potential bottlenecks and optimizes resource allocation to minimize disruptions.

Testing and Quality Management

AI enhances testing processes, ensuring products meet quality and regulatory standards before release.

- Efficiency in Testing: AI identifies high-risk areas in designs, automates repetitive tests, and accelerates validation processes.

- Product Validation: Machine learning algorithms simulate product performance under various conditions, improving reliability and compliance.

Deployment and Maintenance

In deployment and maintenance, AI ensures product performance remains optimal throughout its lifecycle.

- Predictive Maintenance: AI anticipates maintenance needs using sensor data and predictive analytics, reducing unexpected failures and downtime.

- Real-Time Monitoring: AI-driven monitoring systems track product usage and health, enabling businesses to address issues proactively.

By integrating AI across all stages of the product lifecycle, businesses can enhance efficiency, reduce costs, and deliver superior products to market. These applications demonstrate how AI-powered PLM solutions are shaping the future of product innovation and management.

AI-Driven PLM Tools and Software

Leveraging AI with Visure Requirements ALM Platform for PLM

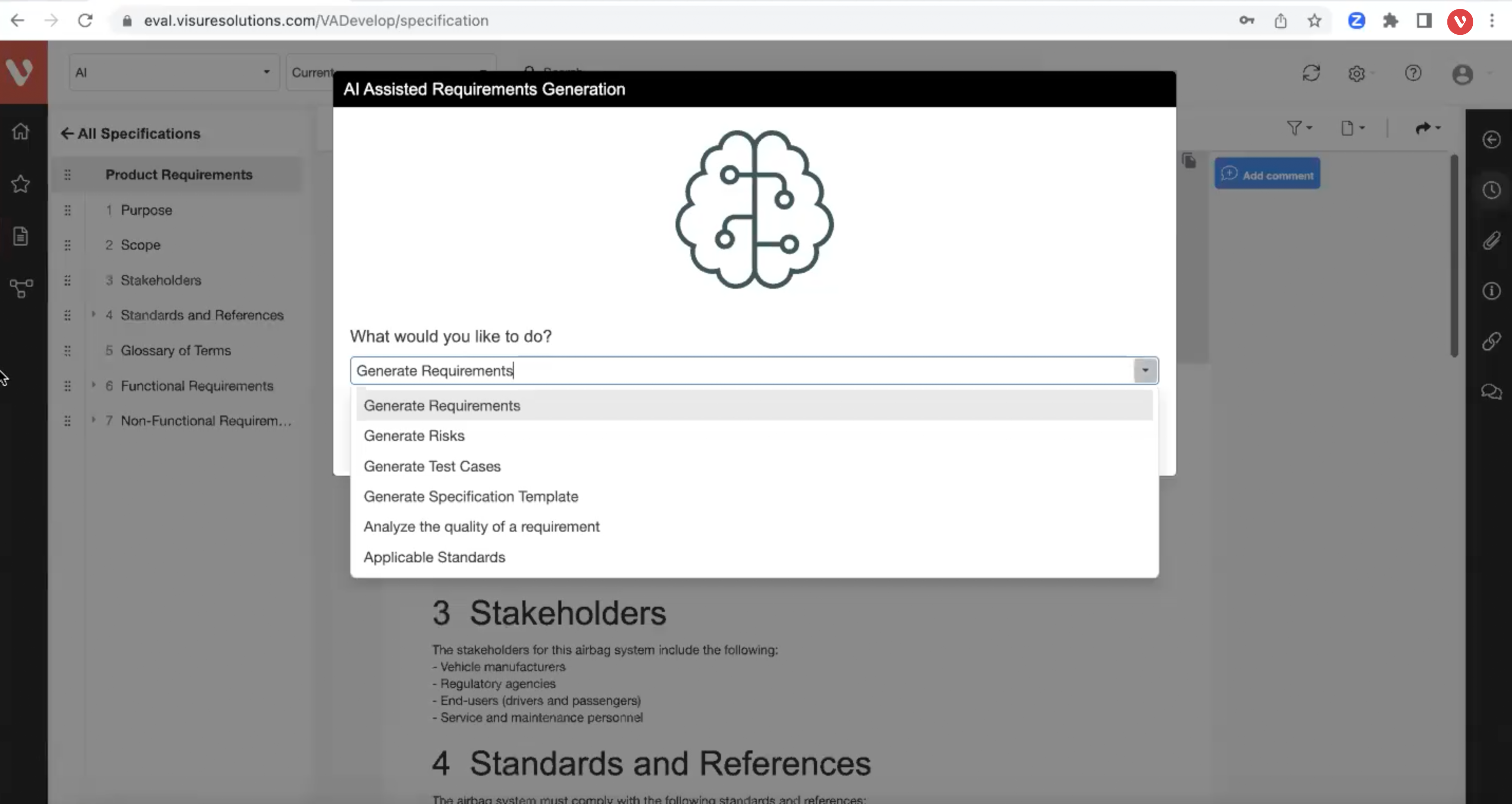

The Visure Requirements ALM Platform, integrated with AI-driven capabilities, offers a transformative solution for streamlining Product Lifecycle Management (PLM). By combining advanced Artificial Intelligence (AI) features with robust requirements management tools, Visure empowers businesses to optimize every phase of the product lifecycle.

How Visure AI Enhances Product Lifecycle Management?

Intelligent Requirements Gathering and Definition

Visure’s AI-powered assistant simplifies the complex task of gathering and defining product requirements by:

- Automating requirement elicitation using natural language processing (NLP) to interpret stakeholder needs and convert them into actionable requirements.

- Suggesting optimized requirement structures to reduce ambiguities and improve clarity.

- Identifying missing or inconsistent requirements early in the development process.

Enhanced Traceability Across the Lifecycle

With AI-driven traceability, Visure ensures:

- End-to-end alignment of requirements, design, testing, and deployment processes.

- Automated detection of traceability gaps and the generation of compliance reports.

- Real-time updates and change management to maintain synchronization across teams.

Automated Testing and Validation

AI integration in Visure supports automated testing processes, including:

- Generating test cases directly from defined requirements to ensure comprehensive coverage.

- Identifying potential quality issues through predictive analytics and historical data analysis.

- Streamlining validation workflows for faster time-to-market.

Predictive Analytics for Proactive Decision-Making

Visure’s AI features enable smarter decision-making by:

- Forecasting potential risks, resource bottlenecks, and project delays.

- Providing actionable insights through real-time data monitoring and analysis.

- Recommending strategies to improve product design, reduce costs, and meet deadlines efficiently.

Collaboration and Communication Optimization

Visure AI-powered tools enhance team collaboration by:

- Offering a centralized platform for seamless communication between stakeholders, designers, and engineers.

- Facilitating real-time updates, ensuring teams remain aligned on goals and timelines.

- Providing AI-driven contextual suggestions to improve decision-making during reviews.

Benefits of Visure’s AI-Driven PLM Solution

- Efficiency Gains: Automates repetitive tasks, reducing manual effort and errors.

- Improved Product Quality: Ensures requirements are accurately translated into deliverables.

- Faster Time-to-Market: Streamlines workflows, minimizing delays across product lifecycle stages.

- Compliance Assurance: Tracks regulatory standards and generates audit-ready reports.

By leveraging Visure Requirements ALM Platform with AI capabilities, businesses can achieve a fully optimized product lifecycle management process, fostering innovation, enhancing productivity, and maintaining a competitive edge in today’s dynamic markets.

Future of AI in Product Lifecycle Management (PLM)

Trends Shaping the Future of AI-Driven PLM

The integration of Artificial Intelligence (AI) in Product Lifecycle Management (PLM) is rapidly evolving. Key trends influencing this future include:

- Hyperautomation: AI-driven PLM systems will increasingly automate workflows across the lifecycle, from design to maintenance, minimizing manual intervention.

- Personalized Products: AI’s ability to analyze consumer data enables mass customization and the development of highly tailored solutions.

- AI-Augmented Decision-Making: Advanced machine learning models will enhance predictive analytics, enabling organizations to make data-driven decisions faster.

- Scalability and Cloud Integration: AI-powered PLM tools will leverage cloud computing to support global collaboration and scalability for enterprises of all sizes.

Emerging Technologies in AI-Driven PLM

AI-powered PLM solutions will increasingly integrate with cutting-edge technologies, such as:

- Internet of Things (IoT): IoT devices provide real-time data on product performance, enabling AI algorithms to:

- Predict failures and recommend maintenance schedules.

- Enhance product designs using data insights from connected devices in the field.

- Digital Twins: AI and digital twin technology will simulate products and processes virtually, enabling:

- Accurate modeling of product behavior in real-world conditions.

- Enhanced testing and validation without physical prototypes.

- Faster iteration cycles by optimizing designs based on digital twin insights.

AI-Powered PLM Solutions in Sustainable Product Development

Sustainability is a growing priority, and AI-powered PLM tools play a critical role in achieving eco-friendly product lifecycle management:

- Material Optimization: AI helps select sustainable materials and reduce waste during production.

- Lifecycle Impact Analysis: Machine learning models evaluate the environmental impact of products throughout their lifecycle, from sourcing to disposal.

- Energy Efficiency: AI optimizes energy usage in manufacturing processes, lowering carbon footprints.

- Recycling and Reuse: AI aids in designing products that are easier to recycle and reuse, promoting circular economy principles.

The future of AI in Product Lifecycle Management lies in its ability to integrate emerging technologies, drive sustainability, and enable businesses to adapt to rapidly changing markets. By leveraging tools that incorporate IoT, digital twins, and sustainability-focused AI algorithms, organizations can create innovative products that meet both consumer needs and environmental goals.

Conclusion: Embracing AI for the Future of Product Lifecycle Management

AI is no longer a futuristic concept but a game-changer in the realm of Product Lifecycle Management (PLM). As we’ve explored, integrating AI into PLM systems not only streamlines every stage—design, development, manufacturing, testing, and maintenance—but also enhances decision-making, fosters collaboration, and ensures sustainability. The future of AI-powered PLM solutions holds even more potential with emerging technologies like IoT and digital twins, driving innovation and transforming industries for years to come.

For businesses looking to stay ahead of the curve, adopting AI-driven PLM tools is key to gaining a competitive edge, optimizing processes, and ensuring long-term sustainability.

Ready to experience the transformative power of AI in Product Lifecycle Management?

Check out Visure’s 14-day free trial and discover how the Visure Requirements ALM Platform can optimize your entire product lifecycle with AI-powered tools today!